One of several Trane

High-efficiency

models

Authorized TRANE Dealer

Leclair Heating & Sheet Metal.

All rights reserved.

2613 McGregor Pl. Thunder Bay, Ontario P7E 5G9

Phone: (807) 623-4655

Gas Furnace types

How a Furnace Works

The basic operating process is the same for all furnaces regardless of the type of fuel they use.

- The thermostat calls for heat and starts the ignition and combustion process. Fuel is delivered to the combustion chamber, mixed with air, and ignited to produce heat in the form of hot gases.

- These hot combustion gases flow through and warm the heat exchanger. The combustion gases exit the furnace and are exhausted from the home.

- A control in the heat exchanger starts the fan which pushes the warm air through the distribution system and thoughout the house.

- This process continues until the room thermostat anticipates enough heat is left in the furnace to bring the house up to the temperature set by the thermostat. The thermostat then tells the burner to shut off. The furnace fan continues to run until the heat exchanger thermostat turns the fan off.

Older "gravity type" furnaces depend upon the natural buoyancy of the hot air to distribute heat within the home. This same natural buoyancy is depended upon to exhaust gases from furnaces. Changes in efficiency of equipment and in the characteristics of homes require that furnaces manufactured today use fans to push the exhaust out of the home.

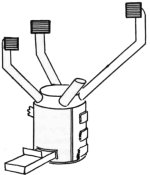

Gravity Furnace

The "Octopus" took up most of the basement, with large pipes running upstairs. Originally coal fired, many were converted to oil and then to natural gas.

The furnace consists of a large cast iron heat exchanger, enclosed in a larger sheet metal cabinet. There is no fan required. The cold air, being heavier than hot air sinks to the floor, through the cold air grates and down to the furnace in the basement, where it is heated and rises through the large warm air pipes to the rooms above.

Being a passive warm air furnace, relying on gravity for air circulation, the temperature in the home is difficult to regulate.

The typical efficiency of this type of furnace is around 1 percent.

Forced Warm Air Furnace

The standard forced air furnace allowed the home owner to reclaim the basement. Not only smaller in size, but installed near the chimney, freeing up all the room previously used by the old Octopus. It was easier to heat the home to a more constant temperature, and it cost less to operate.

Natural gas furnaces are rated by their Annual Fuel Utilization Efficiency (AFUE), which is the ratio of the heat output to the total energy consumed by the furnace.

A standard natural gas or propane furnace with a standing pilot has an AFUE of 55 to 65 per cent, despite a 75 to 80 per cent combustion efficiency. This means that only 55 to 65 per cent of the energy supplied to the furnace is realized as usable heat in the building. The AFUE is lower than the combustion efficiency because heated building air is constantly flowing out of the chimney through the draft hood on the furnace. They use a single stage heat exchanger and indoor air for combustion. The efficiency is lowered further by the standing pilot that generally operates throughout the year (the pilot light can often be shut off if it is not required for the entire year). Standard efficiency units are no longer available on the market.

Mid-Efficiency. A mid efficient natural gas or propane furnace has an AFUE rating of approximately 80 per cent. These also use a single stage heat exchanger, and indoor air for combustion. The efficiency is improved over the standard furnace by replacing the draft hood with an induced draft fan. This eliminates the constant flow of heated building air out through chimney. The furnace also employs electronic ignition, eliminating the standing pilot. Mid-Efficiency furnaces are now being replaced with High-Efficiency models.

High-Efficiency (90 to 97 per cent AFUE). The high efficiency is achieved through the addition of a secondary heat exchanger that recovers an additional 10 to 17 per cent of the heat produced by the burning gas. The cooler exhaust gases are vented using approved plastic venting systems – either through a sidewall or vertically through the roof or a chimney cavity.

How high-efficiency furnaces work

There is no pilot light in a high-efficiency furnace as burner ignition is achieved electronically. In the secondary heat exchanger of a high-efficiency furnace, the combustion gases are cooled to a point where the water vapour condenses, releasing additional heat into the building. The condensate then drains to a floor drain. The exhaust gas is cool enough to be vented through a plastic pipe, which is usually out the side wall of the building.

High-efficiency furnaces have induced draft from sealed burners and take their combustion air through a second plastic pipe from outside the building. These eliminate any loss of heated indoor air through the vent. Depending on the combustion and heat exchange design, fuel savings of up-to-40 per cent relative to standard efficiency gas furnaces can be achieved. Greenhouse gas emissions released into the environment are also reduced. In addition to the natural gas savings, a reduction of 20 to 30 per cent of the electricity used by the furnace fan can be obtained by selecting the variable speed brushless Direct Current Electronically Commutated Motor (DC ECM) blower motor, an alternative to the AC induction motor.

All in all, the new furnace you choose will become a very big part of your energy reduction plan. Choose the most efficient furnace your budget allows. Once it's installed, take care of it and it will take care of lowering your heating costs.