Last week

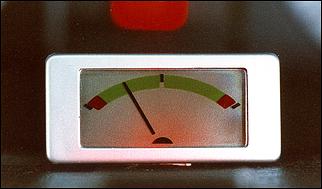

we introduced the Needle Mixture Meter - a simple, cost effective and easy way

of watching the real-time output of your car's oxygen sensor. This week, it's

time to install it.

Dash Mounting

We decided to mount the

Needle Mixture Meter directly in front of the driver, sitting on top of the

steering column cover. A small bracket was made from aluminium, bent into a

right angle. This held the display at the correct angle for best viewing by the

driver, while at the same time not letting the meter obscure any of the normal

instruments. The location also gave plenty of space in front of the meter to

mount the two tiny illumination LEDs, which were concealed within a small

housing made from half of a TV aerial balun cover. (Basically, any small black piece

of plastic with the right shape can be used as a housing.) We used two very

small LEDs, but a single larger LED will also work.

Note that when you buy the

LED(s) - any size, from 3mm to 10mm - you will also need to purchase a 560-ohm

resistor to limit the current flow thru them. Price for both the resistor and a

LED from an electronics store will be under 50 cents. Note also that the long

leg of the LED is the one you connect to positive 12 volts - put the resistor

in this leg to make it even longer! I chose to use two 3mm LEDs, wired in

parallel while still using just the one current limiting resistor.

Alternatively, you can just buy a small 12 volt lamp - hobby stores sell tiny

ones that are used in model railways and the like. Then you don't need to worry

about a resistor or getting the polarity right.

Anyway, our installation

used orange LEDs to match the orange instrumentation lighting being used in my

Audi. The LEDs were powered from the same supply as the Needle Mixture Meter.

This means that whenever the car is running, they are on - not a problem since

the life of the LEDs is likely to be longer than the car.

Wiring

The Audi

has a 3-wire oxygen sensor - earth, a 12V supply for its internal heater, and a

signal output wire. I decided to power the Needle Mixture Meter directly from

the oxygen sensor - since I already needed to have one wire (the signal)

connecting the oxy sensor to the meter, why not have three wires (signal,

power, earth)? In turn I bared each of the three wires leading the oxy sensor,

soldering an insulated wire to each. Note that close up to the oxy sensor often

the wires are made from stainless steel rather than copper, with the stainless

being quite hard to solder to. There are two ways of overcoming this - tap into

the oxy sensor wires closer to the ECU, or use a crimp style connection to the

oxy sensor wires.

I didn't even bother to

work out which wire was which at this stage - I just made my connections,

insulated the joins, and ran the new wires back into the cabin. Then, using a

multimeter, I worked out which was the earth, the signal and the positive 12V

supply wires. The earth connects to the Needle Mixture Meter's black wire, the

positive 12V to the Needle Mixture Meter's red wire, and the oxy sensor signal

goes to the Needle Mixture Meter's white wire. Easy - but don't get them the

wrong way around!

(Just a minor warning note.

On some cars the oxygen sensor heater may turn off when the sensor is up to

temp. If you are powering the meter from the oxygen sensor's heater and you

find that your Needle Mixture Meter suddenly goes off after a few minutes of

running but comes back on again at the next restart - it may be that the heater

switches itself off. However, cars that take this approach are very rare.)

Interpreting the Display

I once read

a post in a discussion group from someone who thought that the output of an

oxygen sensor was a constantly varying voltage. Like, the volts went up and

down because that's the way the sensor worked. Wrong!

However, if

you didn't know what to look for, you could be easily convinced that the output

of the oxy sensor on a factory EFI car is almost random. But it ain't.

Sure,

sometimes you'll see the needle flicking back and forth - quite often actually

- but that's because the air/fuel ratio is actually also going up and down -

rich, lean, rich, lean. It's doing this the whole time that you're in closed

loop - that is, when the oxygen sensor is feeding information back to the ECU

and the ECU is actually paying attention to it.

So by

watching the Needle Mixture Meter, you can immediately see at what loads and

speeds your car works in closed loop. Note that even expensive tail-pipe probe

air/fuel ratio meters can't see the alternating mixtures as well as the Needle

Mixture Meter.

So why

would you care if your car is in closed loop? Here are two reasons:

·

Modifications made to the mixtures by using an interceptor

module or changing fuel pressure will not be retained when your car is

in closed loop. That is, closed loop mods will be subsequently "learned

out". Now if your car is still in closed loop at a fairly high load (and

that's the case with some cars), then it's only at higher loads than

this that these types of tuning changes will be retained. So when your friendly

workshop tells you how they've made your car more economical by using an

interceptor to lean the mixtures when you're cruising at 100 km/h, you can say

"Crap, it's still in closed loop at 100." And watch their jaws

drop...

·

If the oxygen sensor is getting tired, the voltage

oscillations (the speed of the needle movement) will be slow. If the oxy

sensor's dead - the needle won't move ever. Some cars will have the needle a

flickering blur in closed loop, so quickly are the mixtures changing back and

forth.

So what will happen on the

display when you first start the car? Firstly, in some cars, the meter needle

with stay at the full lefthand position until the oxy sensor warms up. (On

other cars a bias voltage is applied, resulting in the needle immediately

jumping to about the middle.). Then, as the sensor gets hot, the needle will

become active. Soon it will be flicking back and forth across the scale,

showing that you're in closed loop. Give the engine a burst of throttle, and

you'll see the needle jump across to the right as the mixtures go richer in

response to the throttle input. Then, on the overrun, the needle will go full

left (lean) as the injectors shut off.

So, not only can you

monitor closed loop behaviour, you can also see a heap of other things:

·

Rich warm-up mixtures

·

Rich full-load mixtures

·

Ultra-lean trailing throttle mixtures

·

And, perhaps, lean cruise mixtures (None of my cars have

ever had a lean cruise ECU function, so I can't be certain that you'd be able

to see it. But I think that you would!)

If you are

running your car on programmable management, you will still be able to see the

range of mixtures that is being used - although the closed loop fluctuations

usually won't happen as closed-loop programmable ECUs are rare. To reiterate a

point made earlier, the Needle Mixture Meter is not sufficiently

accurate to allow you to do full load tuning, but it will certainly give you a

very useful real time guide as to what is going on.

Conclusion

Once you've

driven around with the Needle Mixture Meter telling its flickering tale, it's

very hard to go back to having no mixture indication. And I tell you one thing

- if, after you've fitted the display, you're driving along and the engine

stumbles or develops a flat spot, I bet of all your gauges it's the Needle

Mixture Meter that you'll look at first...

Through

the AutoSpeed

Shop the EMA 1710 Needle Mixture Meter costs AUD$78, plus $7 freight within

Australia. (For overseas shipping rates, add the item to your shopping cart and

change the country drop down box.)