Firstly,

before you all ask, this is not the digital air/fuel ratio meter that

AutoSpeed and Labtronics have been working on (and are continuing to develop).

Nor is it a direct replacement for one of the most popular dot-type LED Mixture

Meters in the world - my design described at "Cheaply Monitoring

Air/Fuel Ratios" and available from the AutoSpeed Shop

through Jaycar Electronics.

Nope, this is another completely different

unit, although in many respects it's like a different version of the LED

Mixture Meter. Like that meter, the Needle Mixture Meter displays the voltage

output of the standard exhaust gas oxygen sensor. This is the sensor that's in

pretty well all cars of the last 15 years. It's worth fitting a gauge to

monitor the output of the oxy sensor because the sensor develops a high voltage

output (eg above 0.8V) when mixtures are rich, and low voltage (like less than

0.2V) when mixtures are lean.

Note that any meter that uses the raw output

of the oxygen sensor is not accurate enough for the tuning of programmable

management, but this is certainly not to say that it's not a useful

instrument. (For more technical details on oxygen sensor characteristics, go to

"The Technology of

Oxygen Sensors" ) With the Needle Mixture Meter installed, you'll be

able to tell at a glance exactly when your car is in closed loop (ie the oxygen

sensor is controlling the air/fuel ratio), whether you have a fuel starvation

problem (maybe your pump is dying or the fuel filter is blocked), or if the car

is running uncharacteristically too rich (maybe you've forgotten to tighten

that clamp after the airflow meter!).

So what are the advantages of the Needle

Mixture Meter over the still-available LED meter?

·

Although it uses an analog needle, it is in fact an LCD

display that samples 10 times a second

·

It is available completely built, so no electronic

construction is required - just buy it and connect the three wires

·

It is very easy to read, even in direct sunlight

·

It looks good - in comparison, the fabricated LED meter is

really hard to install into a dash without it looking a bit gumby

·

It is much smaller in all dimensions - really tiny in fact

at 43.5 x 21.4 x 5mm (WxHxD)

And the

disadvantages over the LED Mixture Meter?

·

It costs a lot more

·

To be seen at night it needs illumination (we'll overcome

that one in a moment)

·

It has very slightly poorer resolution (down in this regard

by 10 per cent)

To be

honest, just the fact that that it is easy to make it look good on the dash

(ever tried to drill the 10 LED holes in a straight line?) was enough to sway

us.

The Meter

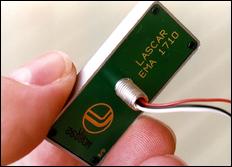

Built by

Lascar Electronics, the meter is model number EMA 1710. While it's not intended

to be used to monitor the output of the oxygen sensor, out of the box it is

perfect for this application. Why? Because it can be powered by voltages from

5-12 volts and has a Full Scale Deflection (ie max needle movement) of just 1

volt. All that it needs is for the black wire from the meter to be earthed, the

red wire connected to an ignition-switched 12-volt source, and the white wire

to be connected to the output of the oxygen sensor. (The green and red markings

on the meter's face don't mean anything in this Mixture Meter application.)

And you don't need to make

a hard-to-make rectangular cut-out in the panel to mount it, either! Instead,

the meter sits on the surface of the panel - but since it's only 5mm thick,

it's barely projecting any further than a bezel would anyway. Just a single

5.5mm hole needs to be drilled in the panel, with a threaded fastener on the

back of the meter projecting through it. The meter's wires come out of the

middle of the fastener, so it's just a case of slipping the (supplied)

shakeproof washer and nut over the wires, placing them onto the stud, and then

tightening the nut to hold the meter into place.

The display is small enough

to actually build into the instrument cluster itself - though remember that it

needs to be externally illuminated - and even on the most crowded of dashes,

there will be plenty of places where it can be neatly mounted. If your car uses

two oxygen sensors, the displays are easily small enough to be mounted

side-by-side without taking up too much space.

Now at this point you all

wanna know how much a display costs, don't you? Well, through the AutoSpeed

shop the EMA 1710 costs AUD$85, freight free within Australia. (In US dollars

that's around forty bucks - put it in your cart and change the destination

country for overseas freight rates.)

Installing It

The hardest

part of the installation process is finding which wire from the oxygen sensor

to connect to the white wire from the Needle Mixture Meter.

If you have

a car which features an oxygen sensor with just one wire coming from it - then

that's the one. Bare a short length of this wire (preferably back a bit from

the sensor), and solder the white wire from the Needle Mixture Meter to it.

(Well you prob don't want to sit in the engine bay or under the car to read the

meter, so you'll need to extend the Needle Mixture Meter's white wire

first....).

But it's

much more likely that you'll have an oxy sensor in your car that has three

wires coming from it. The three wires will be:

·

Earth

·

12V

·

signal

...and it's

the signal wire that you're interested in. You can either consult the workshop

manual to find out by the colour codes which wire is which, or you can use a

multimeter.

To use a meter, start the

car and let it warm right up (you might even want to go for a drive first).

Leave the engine running, earth the black probe of the multimeter, and then

with the meter set to measure voltages, use the red probe to tap into the wires

going to the oxygen sensor. On one wire you'll find 12 volts (actually prob

13.8 volts with the car running). On another wire you'll find zero volts, and

on the third you should see a very small fluctuating voltage, around 0.5-0.6V.

If you rev the car, this voltage should quickly change.

And it's to this sensor

wire that you need to connect to the white wire from the Needle Mixture Meter.

Mounting It

The Needle

Mixture Meter is so light and small that it's a good idea to first temporarily

mount it on the dash with Blu-Tac. That way, you can easily assess how visible

it is in a variety of locations - just move it around until you find the best

spot.

When

deciding on the best location, make sure that the display is visible when

you're in different gears (it'll often be obscured in first or third or fifth

if you locate it low at the front of the centre console), that reflections from

the display's screen don't occur, and that it won't be a distracting reflection

in the windscreen at night.

The actual

mounting process then won't take long:

1. Decide on the

right spot

2. Drill a hole

3. Push the wires

through the hole

4. Locate the

meter

5. Do up the nut

6. Remove the

protective blue plastic strip from the face of the meter

However, if you want to be

able to see your Needle Mixture Meter clearly at night, some illumination of

its face will be good. The best way is to locate the meter so that a shielded

LED can be placed in front of it, with the LED's light directed back at the

meter. (The more of an angle between the LED light and the meter's face, the

less effective the illumination will be.) You can pick the colour of the LED to

match the colour of your instrumentation lighting - from white to orange to

green to red. Alternatively, you can simply use a miniature 12V bulb, of the

sort available from hobby stores.

Next week: Using the Needle Mixture

Meter!